Unmatched Innovation.

Unlimited Applications.

Green Eagle Reinforced technology makes plastic profiles up to 20X stronger.

A typical PVC extrusion is non-structural and needs a secondary part such as metal or wood inserted as a stiffener. Having worked with plastic extrusion his entire career, inventor and owner Guerry Green began working in 2015 on an idea to strengthen plastic profiles without the weight of wood or the corrosive and conductivity issues with metals. The result is Green Eagle’s patented technology that combines waste stream fibers with revolutionary manufacturing techniques to create a composite laminate material that can easily be inserted into plastic profiles during the extrusion process, reinforcing and making them incredibly stronger. Now ready for commercial applications, Green Eagle is collaborating with extruders, engineers, product developers and others looking for new ways to strengthen their plastic profiles.

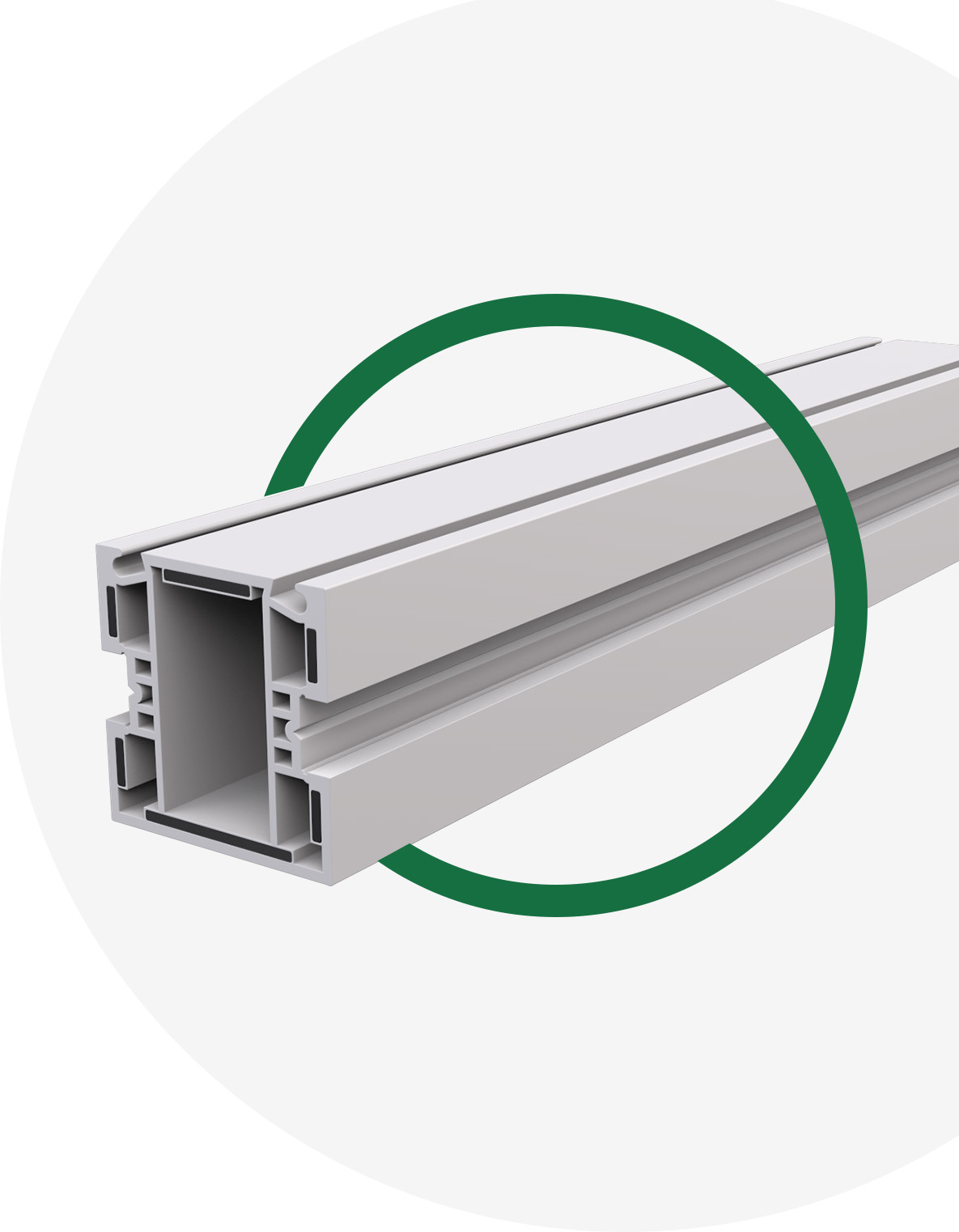

How does it work?

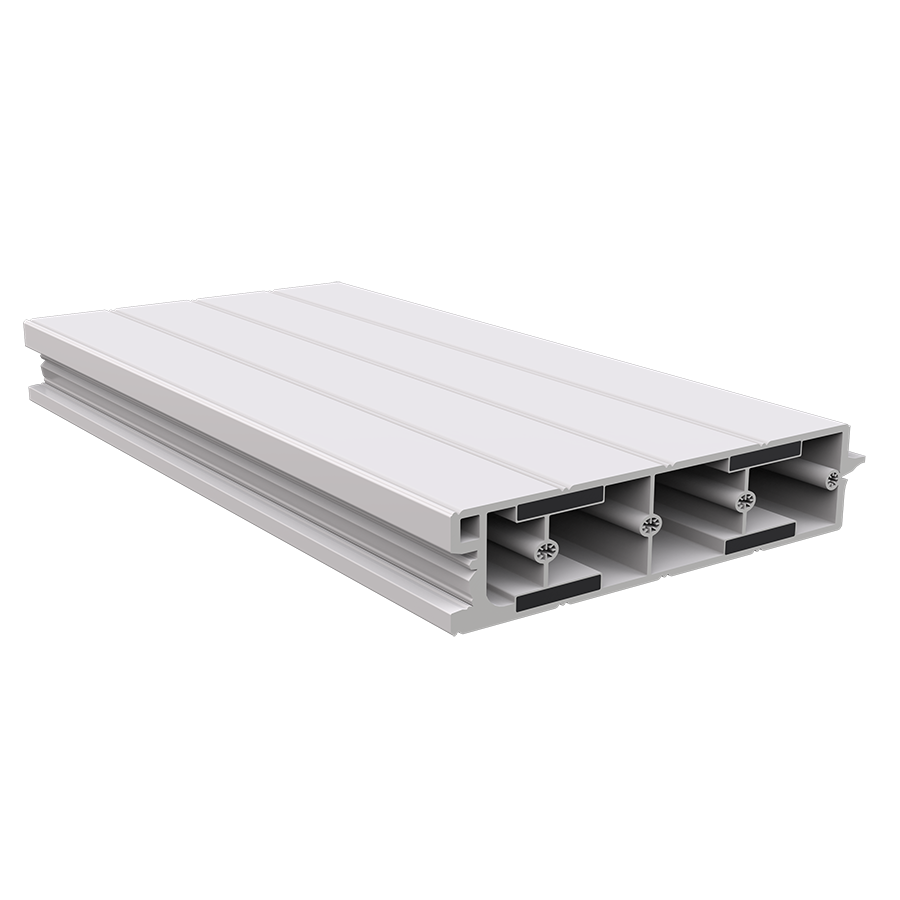

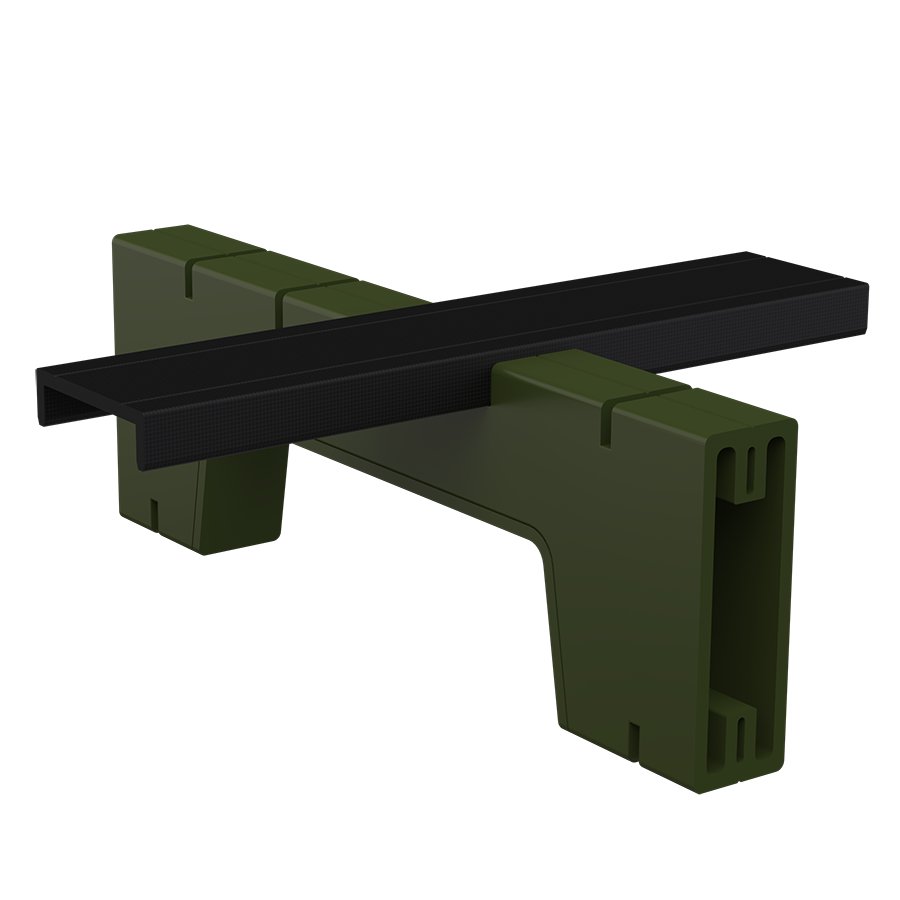

The Green Eagle process combines waste-stream materials with basic engineering models to achieve a plastic profile with unheard-of strength, rigidity and stability. Our unique process creates a composite laminate of polymers and fibers (including carbon fiber, fiberglass, and natural fibers) that is then inserted into a plastic profile during the extrusion process. Much like a steel I-beam in a building, the placement of the composite is calculated to provide the greatest performance benefit with the least amount of material, making the plastic profile up to 20X stronger. The Green Eagle process is protected by over 40 U.S. and International patents.

Unlimited Opportunities

The typical PVC extrusion is nonstructural and the pliability of plastic limits its uses and applications. The Green Eagle Reinforced technology negates the need for wood or metal stiffeners and allows for the use of plastics in areas that previously would never be considered. We at Green Eagle want to work with you and help you use our technology to create exciting new product opportunities.

Uses and Possibilities

Green Eagle has revolutionized the uses and applications for extruded plastic profiles. The possibilities are endless, from building materials to industrial applications, plastic profiles can now be considered in ways never before imagined. For example, decking, siding, windows, shutters and doors, and railing are just a few examples of building products that often use materials such as aluminum inserts to achieve the stiffness required by building codes. Green Eagle Reinforced technology will strengthen your plastic products without traditional stiffening materials.

Green Eagle Deck Board

Green Eagle Door Profile

Green Eagle Door Jamb

Green Eagle Pallet System

Benefits of Green Eagle

Proven technology

Sustainable closed loop manufacturing process utilizing recycled materials

Repurposing

Low-value materials converted to high-value end use composite

Multi-Use

Greatly expands the use potential for PVC and other plastic profiles

The Green Eagle Process is Truly Green

The Green Eagle process will allow for the mass recycling of waste materials while creating high value for our partners and end customers — and the market is worldwide. Our profile manufacturing process reduces landfill waste, reduces the use of raw materials, and minimizes harm to the environment. The waste stream products that we utilize include:

- PET and PETG polymers, which typically come from water and other beverage bottles, packaging, and other consumer products.

- Carbon fiber is a relatively new material often used in aviation, sporting goods and automotive applications, along with many other uses. The fiber is difficult to recycle, and typically ends up in the landfill. We have a contract with a major aircraft manufacturing company to take their carbon fiber waste and convert it into our reinforcing material.

- Fiberglass has been around since World War II. At least 30% of fiberglass has always ended up in the landfills. Our process utilizes the strength of reclaimed fiberglass.

- Natural fibers can also be used in our process, whether from waste streams or sourced from farms.

Why Green Eagle?

Our plastic profile reinforcing technology is proven, and it’s now at the stage of application development. Green Eagle is ready to explore opportunities with extruders, product developers, engineers and anyone looking to produce plastic profiles in new, innovative ways. Contact us today to begin a conversation on how we can help you create amazing new products.